|

BASINTUTHU STOVE TEST | |

|

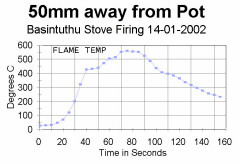

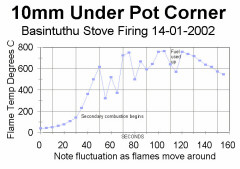

Testing of stoves involves determining how much fuel is used to perform various tasks. The reason for the interest in fuel and stove efficiency is that most fuel used in stoves in biomass (mostly from trees and bushes). This fuel has to be collected by someone, usually women and children. If a stove that can burn less fuel is affordable and convenient to use, people switching to a fuel-saving technology can save time collecting fuel. This stretches the existing resource and saves labour. Some stoves are specifically designed to burn small diameter fuel which can be described as 'kindling'. The small branches of bushes and scrubby trees frequently have such fuel as a significant proportion of their total wood mass. This fuel is frequentl left on the ground when people collect firewood as it is not deemed to be a very useful fuel. In some countries it is the only fuel available but it is burned in a very wasteful fashion in open fires. The Basintuthu Stove (pronounced baa-sin-doo-too, "makes fire from smoke") is a stove designed to burn small diameter wood and twigs efficiently, combining preheated primary air, preheated secondary air and secondary combustion. This means that nearly all the available heat contained within the biomass fuel can be liberated. It also means there there is less smoke, particulate matter and Carbon Monoxide (CO) emitted, compared with most other stoves and open fires. The Basintuthu Stove is constructed from a 25 litre paint can. It has grooves in the sides which provide support for components at certain points. This allows for the stove parts to be nested for shipment and later assembled without welding. There is a top deck which supports the pot grate, an air control ring to close the air supply holes, a secondary air preheating tube and a basket-type fire grate. Inside the top section there is a flame shield to protect the outside top of the stove from heating up too muh and to reflect the flame's heat back to the pot. The pot (a 4 litre aluminum pot with lid) sits inside the upper section to give maximum heat transfer and to shield it from the wind. This stove burns and heats the pot efficiently in a brisk wind. The rotating air control sleeve has 5 holes in it that match 5 similar holes on the lower portion of the stove body. When the sleeve is slid around the stove, the air supply to the fire is closed of. This gives a measure of control over the fire's heat output. The most effective way to control the heat output is to let the fuel burn down and simply put less in as time passes. The average fuel load is between 300 and 700 grammes of wood. RAPID BOILING TESTS Details: Reported to stoves@crest.org on 7-Jan-2002 Date of Test: 7 January 2002 @ 6PM Mean air temperature: 27 deg C Mass of water: 1000gm Mass of aluminum pot: 510gm (the test was done with an open pot so I could try to assess when it was boiling) Mass of water + pot: 1510gm Mass of paper used to ignite kindling: 4gm Mass of pine fuel put into the basket grate: 246gm Mass of all fuel in the basket grate: 250gm Mass of fuel added during the test: none Mass of water + pot at 2 minutes 40 seconds: 1430gm Initial Water temperature: 22 deg C Final water temperature (est from previous experiments): 96 deg C Method: I found it very difficult to light the fire and start the stopwatch at the same time. I decided to light a piece of newspaper rolled up so it wouldn't go out as a match can when simultaneously holding a stove up in the air and starting a stopwatch at the same time. I held up the stove in the air so I could bottom-light it with the end of the rolled up newspaper and when the paper in the grate bottom caught alight, I put the stove down on the ground. From starting the ignition of the paper to putting it down was about 7-10 seconds I guess. Then I immediately put the pot of water on the stove and started the stopwatch. This took about another 2 seconds. From starting to light the paper under the pine pieces until the pot was in place on the stove was about 12 seconds and I didn't time that part because it was impractical to do so. With the stop watch running, I balanced three paint cans on the upper part of the stove to increase the draft. By the time I finished this process the fire was smoking hard. I would have preferred to have the chimney in place, the pot covered and the watch started when the flame hit the paper but I am working alone here. I was recording the time the pot was on the heat and the 'head start' the fire got was minimal. The fire shield around the pot was not present during this test which would have increased the heat transfer to the pot sides, however the pot was encased by the chimney protecting it from any wind. I let it burn. The combustion 'went secondary' after about 45 seconds leaving me with substantially clean smoke and I could look down the paint cans and see the top of the water in the open pot, in theory. Unfortunately there was so much combustion product coming at me and what with the pot being underlit with a roaring red-fellow flame, and the water being in the dark, so I couldn't see the water surface. I ran to the pick-up truck for a powerful flashlight to shine down and this allowed me to take a peek occasionally. Before 1 minute 30 I heard the sound of boiling and I shone the light down through the fumes. I could hear strong hissing and clearly see that the top of the water was severely agitated but I was not sure if it was perhaps caused by the roaring fire and gasses passing around the pot. I let it run until the 2 minute mark and removed the three paint cans. It was boiling vigorously. I left the pot boiling without the extra draft for another 30 seconds. At 2 minutes 40 seconds I removed the pot from the stove and placed it on the scale and let it stabilize. I found that the water had come to a full boil and that additionally 80 gm of water had boiled off in that time of 2:40. |

Basintuthu Stove Type 2 with 1/2 preheated primary and preheated secondary air; heatshield around pot is absent. This stove was used in the test reported below, breaking the unofficial world record for boiling a litre of water by more than 1 minute. The three paint cans used as a chimney to create extra draft are not shown in this picture. The chimney increased the heat output to 25 kilowatts for a brief time. Basintuthu Stove Type 1 with preheated primary and secondary shown here wired and weighed for a fuel efficiency test. The best test to date shows that 35% of the heat energy in the fuelwood gets into the water in the pot. The tests are run with 3000cc of water in a 4 litre aluminum pot.  Crispin, the stove developer, monitoring a biomass fuel briquette burning test.  With the pot lifted you can see the Basket Grate in which the fire is lit, the X-shaped pot grate or stand, the black heat shield inside the top of the stove body and the burning newspaper+sawdust briquettes.  200 grams of briquettes are put onto a small initial wood fire. They normlaly burn for 5-6 minutes each (12 per hour).  Secondary combustion is well under way within seconds. Note the absence of smoke, and notice the presence of what looks like small gas jets coming in from the side of the basket grate. These are hot jets of preheated secondary air igniting the (smoke) products of the primary combustion taking place further down.  |

|

| << Back | ||